The KISS PRESS is a machine developed to give our customers an ironing, shining and sandblast machine. Thanks to the independent motorization of the roller operator is possible to synchronize or to vary the speed of the roller with respect to the transport felt in order to achieve particular effects of ironing, not achievable with traditional machines. By adjusting the thickness between the roller and transport felt can be ironed soft leathers and shining the tips keeping unchanged the softness.

A new introduction system, realized by means of two spreading conveyor belts, allows the use of the machine with any type of leathers, eliminating the problems of folds even on big and soft products.

Features:

- Innovative heating system integrated into the roller, which guarantees significant energy savings, with oil bath electrical resistors inserted inside the roller, allowing to eliminate the external control unit for heating the diathermic oil.

- Roller operator motorized with possibility to adjust the working thickness.

- Possibility to synchronize or vary the speeds of chromed and lower pressure rollers.

- Double – spreading conveyor belts, system to hold the leather during the ironing and embossing process.

- Independent handling devices of felt and spreading conveyor belts, controlled by inverter.

- Last generation of hydraulic circuit components to ensure a constant pressure during the processing phases.

- PLC with “Touch Screen “ panel for programming and control of all parameters (hydraulic pressure, working speed, roller temperature, daily and weekly programming for activation preheating rollers, diagnostic problems, ect ).

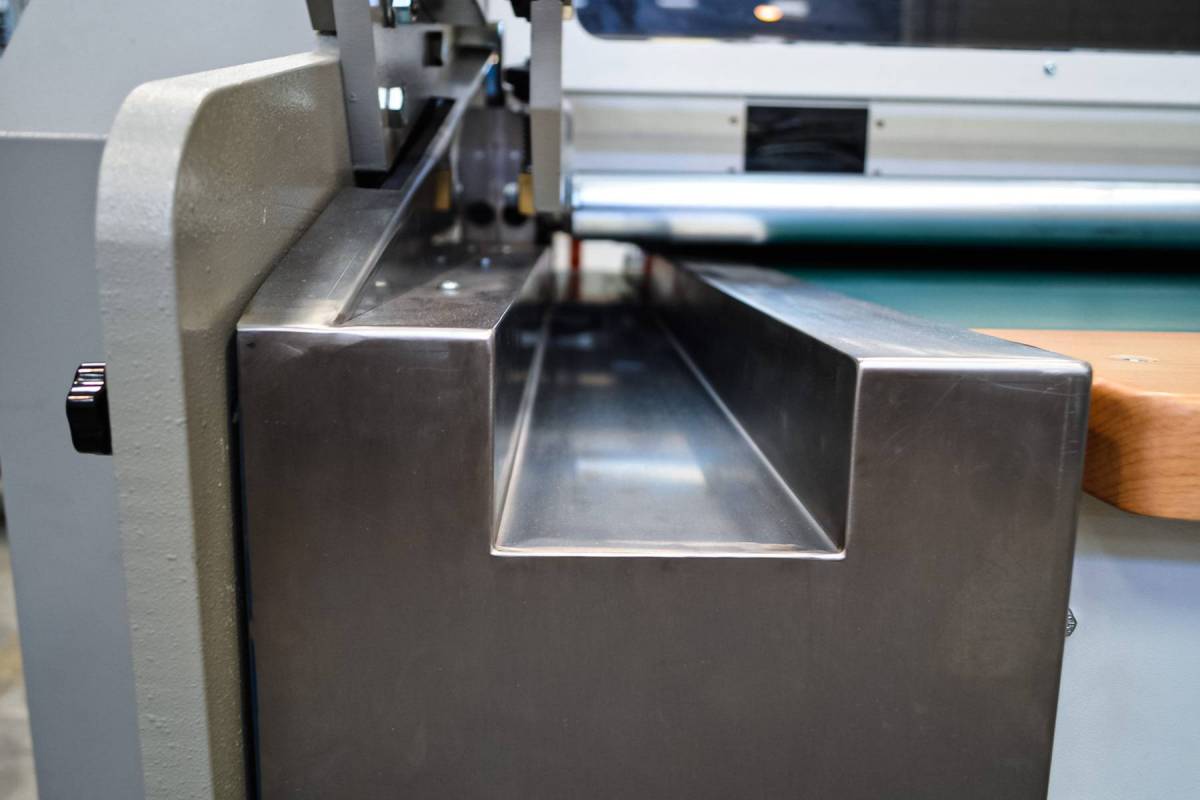

- Detaching device with safety photocell.

- Safety devices in accordance with regulations.